High-capacity thermoforming machine for producing plastic lids, trays, and blister packs using PVC, PET, HIPS, or PLA sheets. Features a large 450×300mm forming area, 15–35 cycles/min speed, and full automation. Ideal for food, electronics, and medical packaging. Built for heavy-duty, 24/7 production with stable output and mold customization options.

Model No :

YK-TF450AProduct Name :

Plastic cup lid forming machinePower Supply :

380V 3P 50HZProduction Capacity :

15-35 cycle/minUsage :

to produce plastic lids,medicine/food/daily/electronics/hardwareShipping Port :

Shanghai/ningbo portLead Time :

35daysWeight :

2200kg

This high-performance thermoforming machine is engineered for the mass production of plastic cup lids, shallow trays, blister packs, and similar thin-wall containers.

Compatible materials include PVC, PET, HIPS, and PLA, making it suitable for a wide range of industries:

Beverage lids (dome/flat/sip type)

Blister packaging for electronics or hardware

Medical trays, meal prep containers, and daily-use food packaging

Multi-cavity trays for supermarket products

|

✅ Max Forming Area: 450mm (Length) × 300mm (Width) × 46mm (Depth)

With a 30cm-wide forming window, this machine supports larger mold sizes and more complex lid/tray structures, significantly increasing per-cycle output. Ideal for multi-cavity mass production with consistent shape accuracy.

|

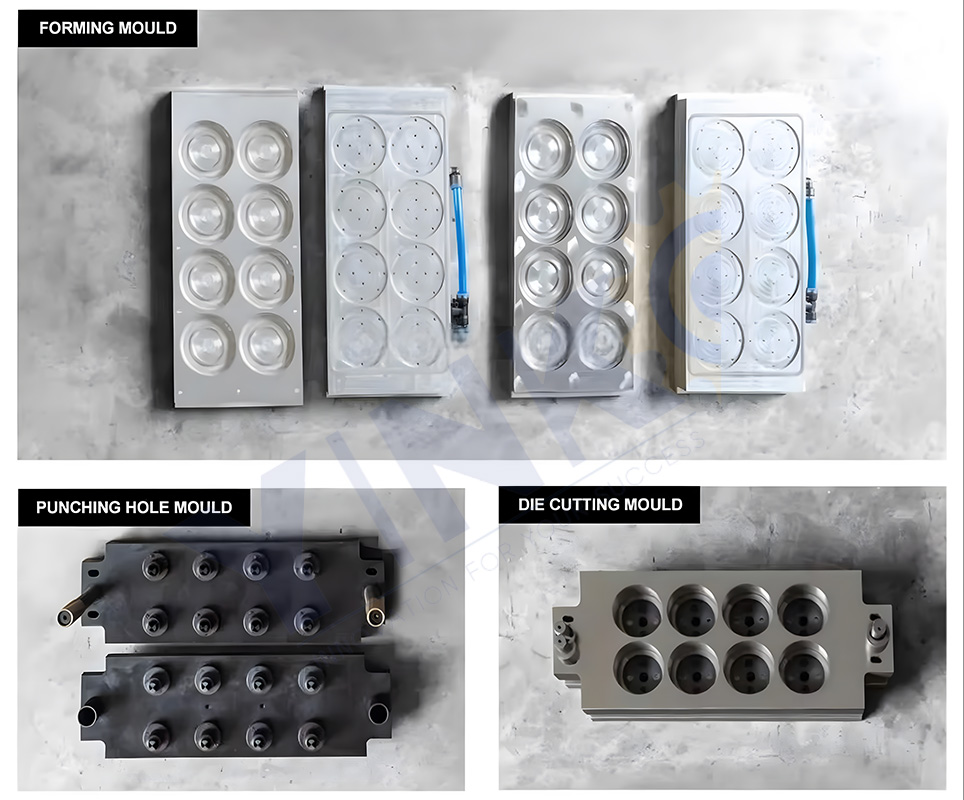

This automatic thermoforming line combines

Roll sheet unwinding & feeding

Electric heating + vacuum/pressure forming

Hole punching, edge cutting & trimming

Stacking and counting of finished lids/trays

Powered by a reliable PLC + touchscreen system, it ensures high precision and minimal scrap rate under 24/7 production.

|

Material Support: PVC / PET / HIPS / PLA

Production Speed: 15–35 cycles per minute

Power Supply: 6 kW total

Air Pressure Requirement: 0.6–1.0 MPa

Air Consumption: ≥ 3m³/min

Cooling Requirement: 60L/h tap or recycled water

Machine Dimensions: 4000×1200×1900 mm

Machine Weight: 2200 kg

Servo-driven feeding with synchronized motion system

Fast mold change and easy adjustment of stroke depth

CE-certified safety enclosure and insulation design

Optional scrap winder and automatic lid stacker

Durable structure suitable for continuous heavy-duty use

|

Beverage cup lid manufacturing

Blister tray factories for electronics & hardware

Food container & meal prep packaging

Custom thermoformed OEM projects

Medical device packaging

Q1: What types of products can I make with YK-TF450A?

A: This model is ideal for producing plastic cup lids (flat, dome, straw-insert types) and small blister packaging used in food, beverage, or cosmetics.

Q2: What materials are supported?

A: The machine is compatible with PET, PVC, HIPS, and PLA sheets. It is not suitable for PP due to PP’s high forming temperature requirements.

Q3: What is the forming area and depth?

A: The forming area is 450mm × 130mm, with a maximum forming depth of 46mm, making it suitable for high-speed production of small to medium-sized lids.

Q4: What is the typical output speed?

A: The machine operates at 15–35 cycles per minute, depending on mold design and material. With a 4–6 cavity layout, hourly output can exceed 9,000 lids.

Q5: Is mold customization available?

A: Yes, we offer custom mold services based on your product specifications or samples. Multi-cavity design and logo embossing are supported.