The YK-TF750 is a high-performance hydraulic plastic thermoforming machine designed for deep-draw applications. Compatible with PP, PS, PET, PVC, and ABS materials, it delivers up to 30 cycles per minute with a generous forming area of 750×400 mm, making it ideal for producing trays, containers, and industrial packaging.

Model No :

YK-TF750Product Name :

Hydraulic Plastic Thermoforming MachinePower Supply :

380V / 50Hz, 3 phase 4 wireProduction Capacity :

30 cycles/minUsage :

make plastic cups/lids/containers etcShipping Port :

Ningbo/ ShanghaiLead Time :

60 daysWeight :

3500kgMaterial :

PP, PS, PET, PVC, ABSRated Power :

160 KWForming Area :

750*400MMMachine Size :

4000*1900*2300mmThe YK-TF750 Hydraulic Plastic Thermoforming Machine is engineered for high-volume production of plastic containers, trays, lids, and industrial packaging using thermoforming technology. With a generous forming area of 750mm x 400mm and a deep draw capacity of 150mm, it is ideal for manufacturing medium- to large-sized plastic products with high precision and efficiency.

|

Food container packaging

Disposable cup and lid production

Industrial plastic tray manufacturing

Medical and pharmaceutical packaging

Cosmetic and hardware blister packaging

|

|

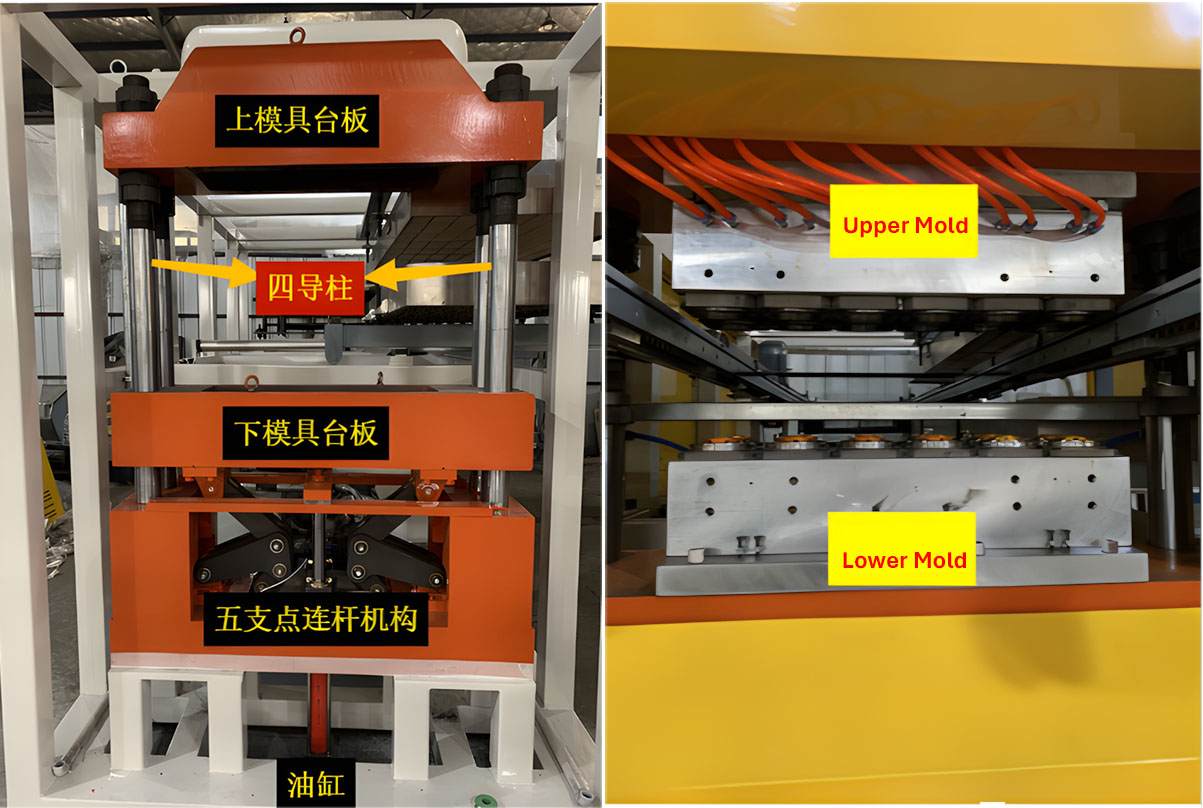

1. Molding cutting system. The working platform adopts a column-guided positioning, which can play a role in stability and balancing force. The mold stretching uses servo stretching. Below the mold, the five-pointed lever principle is adopted. The thrust of the hydraulic cylinder allows the platform to rise and fall, and drives the mold to run up and down smoothly. The operation sequence is: rise - molding - cutting - fall - demolding.

|

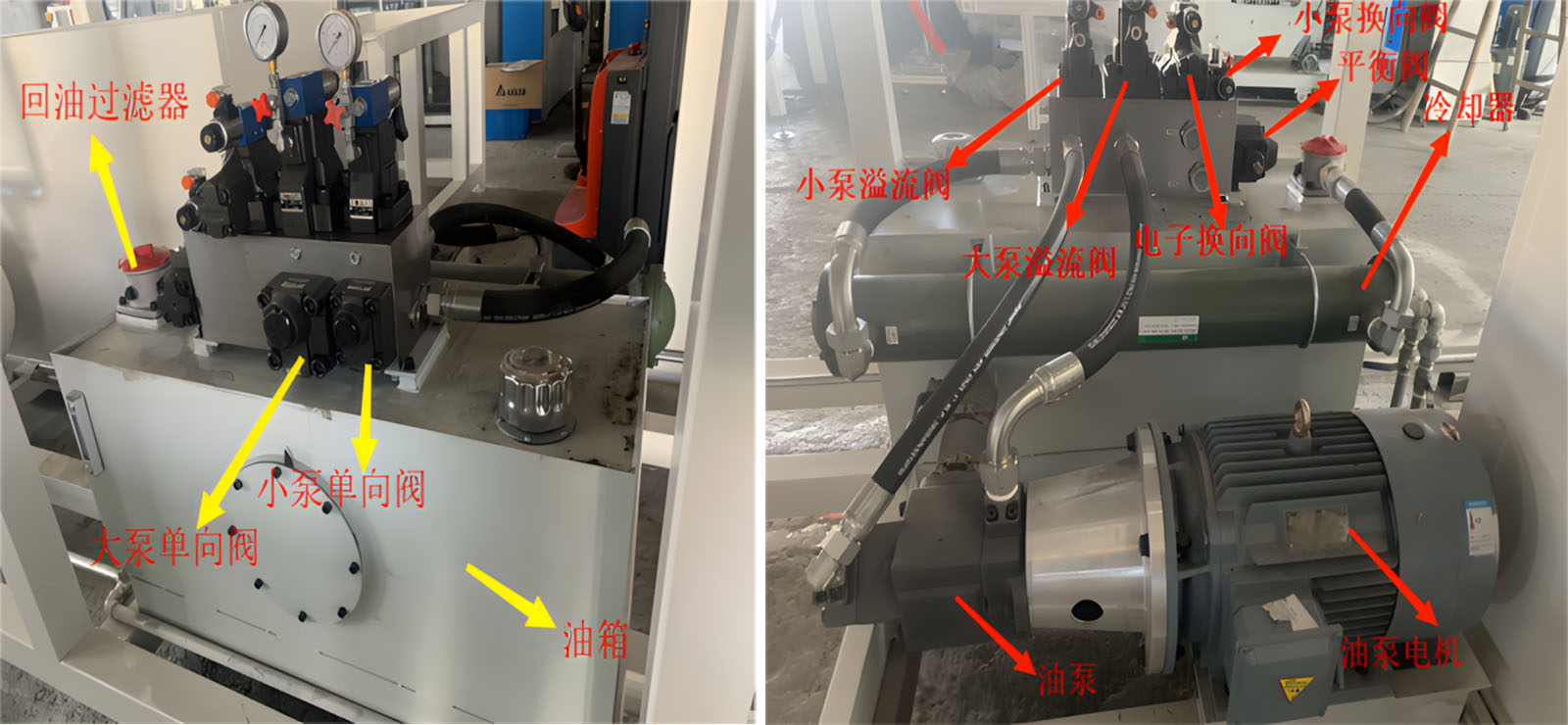

2. Hydraulic drive system. The hydraulic drive has strong stability, providing sufficient working speed and stable impact pressure for the entire molding and cutting action.

|

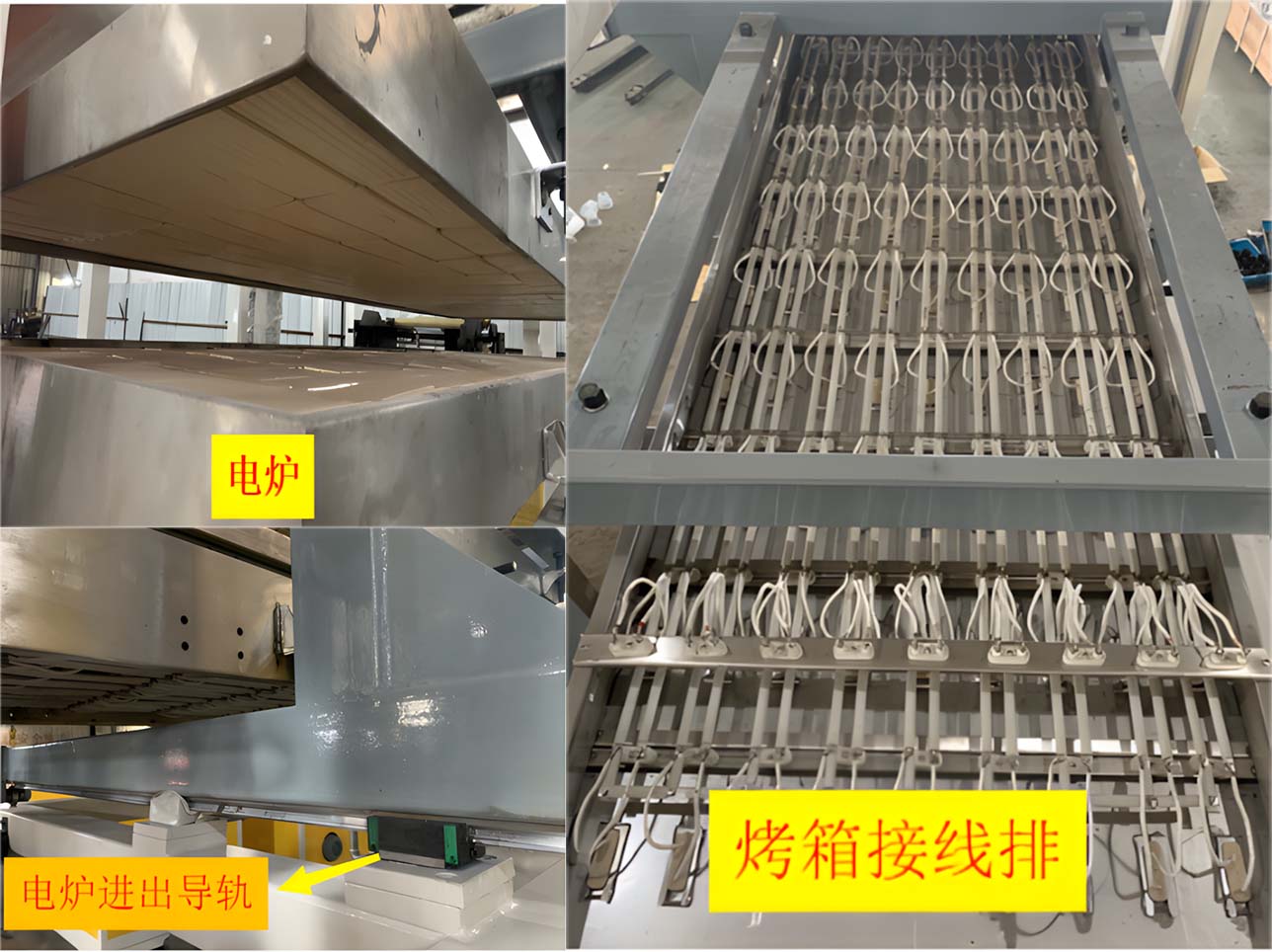

3. Heating system. Divided into the upper furnace (9 zones, 10 rows) and the lower furnace (9 zones, 9 rows). The heating tiles use embedded ceramic far-infrared radiation components with high thermal effect and high safety. The electric furnace is embedded with vacuum insulation cotton, making the temperature distribution more concentrated and more energy-saving.

|

4. Conveyor system and lubrication system. The feeding part uses a variable-frequency motor to convey the sheets, improving the precision and stability of the conveying length. The guide chain tracks are made of mold steel (38crMulv), surface nitrided, with high working surface hardness and long service life. The electric lubricating oil pump is controlled by a computer to automatically inject lubricating oil for maintenance of the mechanical structure at a timed and quantitative rate, extending the service life of the machine.

|

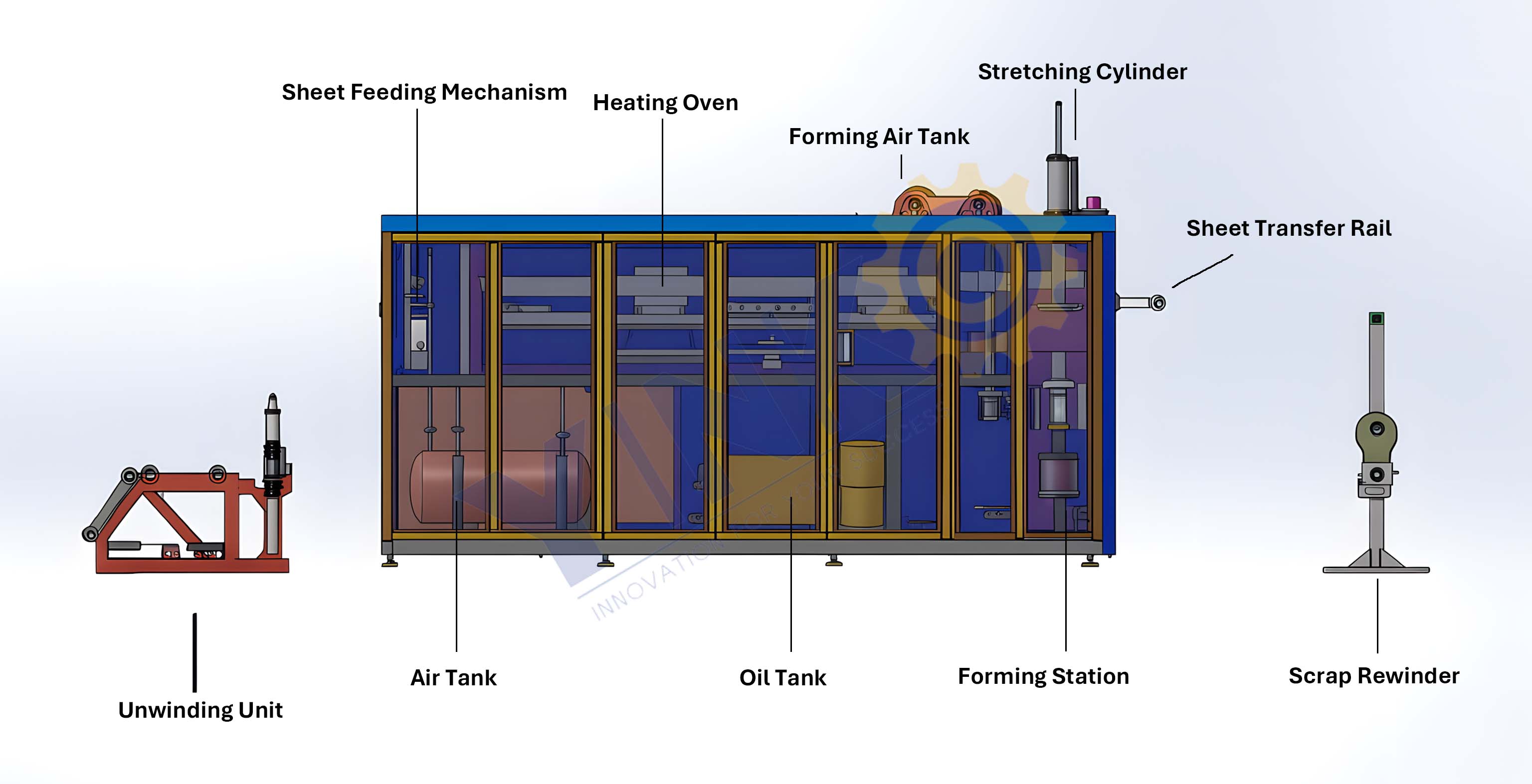

Material Feeding: Plastic sheets are fed automatically from the reel.

Heating: The sheet passes through an oven and is heated evenly to the forming temperature.

Forming: Using hydraulic pressure and vacuum, the heated sheet is shaped within the mold cavity.

Trimming: The formed product is cut using precision die-cutting.

Stacking and Collection: Finished parts are stacked and conveyed out for packing; waste materials are rewound for recycling.

|

|

Applicable materials |

PP, PS, PET, PVC, ABS, HIPS |

|

Maximum forming area |

750*400mm |

|

Maximum forming depth |

150 mm |

|

Applicable sheet thickness |

0.3-2mm |

|

Maximum work efficiency |

30 cycles/min |

|

Overall rated power |

160 kW |

|

Rated heating power |

136.8 kW (171 PCS * 800 W) |

|

Main motor power |

11 kW |

|

Stretching servo power |

5.5 kW |

|

Conveying chain motor power |

4kw |

|

Electric furnace size |

Upper: 2500*850 mm Lower: 2250*850 mm |

|

Power supply |

Three-phase four-wire, 380V 50Hz |

|

Air pressure standard |

0.6-0.8 MPa |

|

Energy consumption |

≈80 kWh |

|

Overall weight |

≈3.5T |

|

External dimensions |

4000*1900*2300mm |

Large Forming Area: 750mm x 350mm allows flexible layout and higher product output.

Deep Draw Capability: 150mm depth supports diverse product shapes.

High-Speed Output: Up to 30 cycles per minute.

Hydraulic Forming System: Ensures strong and uniform forming force.

PLC Control: Offers stable and precise operation with user-friendly HMI.

Material Versatility: Supports a wide range of thermoplastics, including PP and PET.

Q1: What materials are suitable for the YX-750?

A1: The machine supports PP, PS, PET, PVC, and ABS sheets.

Q2: What is the forming speed?

A2: The YX-750 can achieve up to 30 cycles per minute depending on material and mold.

Q3: Can the machine be customized for specific mold sizes?

A3: Yes, we offer mold customization services based on your container design.

Q4: What kind of power supply is required?

A4: The machine uses a 380V 3-phase 50Hz power supply.

Q5: Do you provide training and installation support?

A5: Yes, we offer both on-site and remote training options, along with full installation guidance.